Viscosity Grade Bitumen (VG Bitumen)

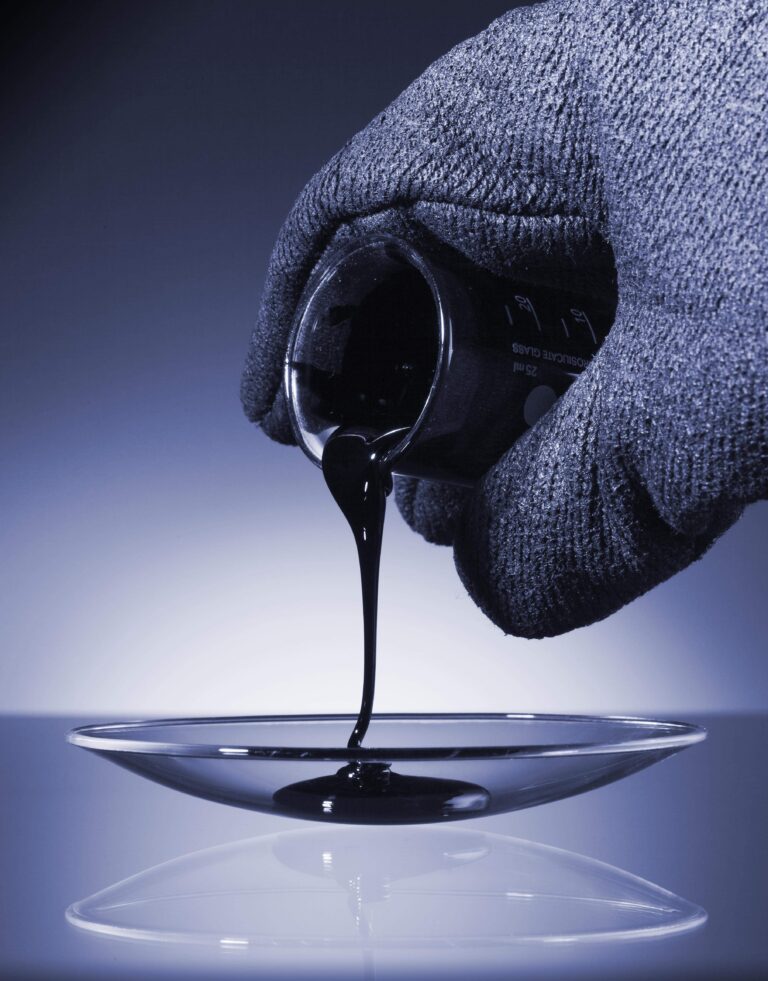

Viscosity bitumen is graded based on viscosity at 60°C and 135°C.

In this type of bitumen, penetration at 25 °C is also measured. These properties help us to understand how bitumen responds to temperature fluctuations.

Viscosity at 60 °C shows bitumen’s resistance to flow in hot climate conditions. On the other hand viscosity at 135 °C determines the behavior of bitumen while its temperature is very high for preparing hot mix asphalt. Penetration at 25 °C measures consistency at room temperature.

Unlike the penetration test, which is an empirical method, the viscosity test of bitumen provides a more fundamental approach to analyzing bitumen’s behavior in a specific range of temperatures.

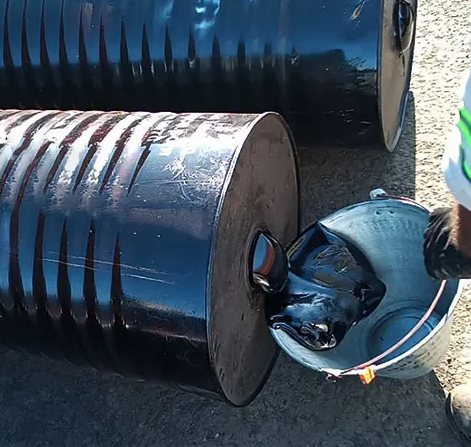

The highest consumption of VG bitumen is in India. Viscosity bitumen has four different grades that are VG10, VG20, VG30, and VG40.